The Fischer-Tropsch Process and Synthetic Oil

How the Nazis Produced Synthetic Oil During World War II

Excerpt from my book The Truth About Energy, Global Warming, and Climate Change: Exposing Climate Lies in an Age of Disinformation

“Germany has virtually no petroleum deposits,” observed Anthony N. Stranges of the Department of History at Texas A&M University, noting a resource reality even today. “Prior to the twentieth century, this was not a serious problem because Germany possessed abundant coal resources. Coal provided for commercial and home heating; it also fulfilled the needs of industry and the military, particularly the navy.”1

In the opening decade of the twentieth century, however, Germany’s fuel requirements began to change. Germany became increasingly dependent upon gasoline and diesel oil engines to fuel automobiles and trucks. Then, the development of commercial airlines made producing aviation fuel another requirement. Germany’s ocean-going ships, including their navy, converted from coal to diesel oil as their energy source. “Petroleum was clearly the fuel of the future,” Stranges noted, and Germany had a problem. How would twentieth-century Germany develop the abundant gasoline and diesel fuel supplies needed to propel a competitive national industrial economy and mount a world-class military operation second to none in Europe without ample petroleum resources?

Then, in the 1920s, German scientists needed to solve this energy problem to fuel Germany into economic recovery following the devastating loss in World War I and the equally disastrous aftermath of the Treaty of Versailles in 1919.

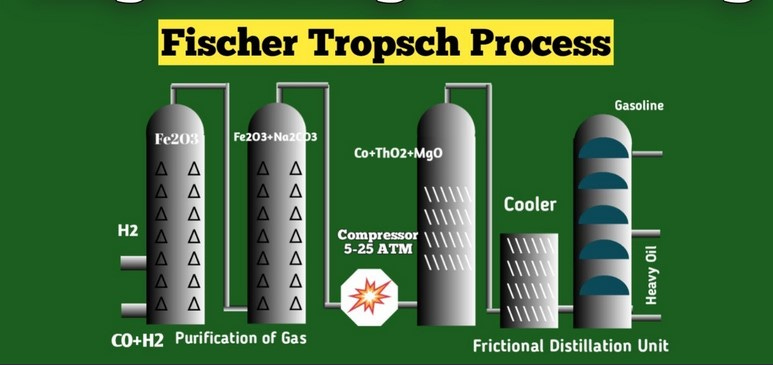

The solution came from two German chemists, Franz Fischer (1877–1947) and Hans Tropsch (1889–1935), working at the Kaiser Wilhelm Institut für Chemie (Kaiser Wilhelm Institute for Chemistry) in Berlin. In the 1920s, Fisher and Tropsch developed a series of equations that became known as the “Fischer-Tropsch process.” Defining a methodology for producing synthetic petroleum from coal, Fisher and Tropsch were aware of the chemistry of carbon monoxide reactions developed since 1900. The hydrogenation of carbon dioxide, producing “water gas” from hydrogen and carbon monoxide, was key to the synthetic production of methane in the early 1900s. In 1923, Fisher and Tropsch realized that alkalized iron turnings (i.e., iron filings resulting as debris from manufacturing processes) at 100–150 atm of hydrogen (i.e., standard atmosphere, with 1 atm being Earth’s atmospheric pressure at sea level), plus carbon monoxide, and 400°-500°C produced synthetic hydrocarbons in a catalyzed reaction.2

In 1925, Fisher and Tropsch began using an iron-zinc oxide preparation as their first catalyst. They went into commercial operation with a cobalt catalyst. In 1937, the Kaiser Wilhelm Institut für Kohlenforschung (Kaiser Wilhelm Institute for Coal Research) developed, on a laboratory scale, alkalized precipitated iron catalysts that ultimately became the standard for commercial Fischer-Tropsch operations. From 1935–1940, Ruhrchemie (Ruhr Chemical) A.G. in Germany developed the Fischer-Tropsch process on a large commercial scale using synthetic gas containing two volumes of hydrogen per volume of carbon monoxide, compressed to about 7 atm through a granular bed of cobalt catalyst at 185°–205°C. The major products of the synthesis were wax, oil, water, gaseous hydrocarbons, and a small amount of carbon dioxide. The hydrocarbons were largely straight-chained alkanes, i.e., saturated hydrocarbons, with the chemical formula CnH2n+2. As German scientists refined the Fischer-Tropsch process through World War II, the process produced twenty different hydrocarbon chemical compounds, ranging from propane (C3H8) to n-butane (C4H10) to benzene (C6H6) to n-octane (C8H18) to n-eicosane (C20H42). With the Fischer-Tropsch process, German scientists could produce synthetic gasoline, diesel fuel, and aviation fuel from coal.3

So, by the 1920s, Fisher and Tropsch had developed a process to produce synthetic hydrocarbons. Their process involved passing hydrogenated carbon gas (H + CO) through an iron (Fe) catalyst at high pressure and intense heat. The result produced methane (CH4) synthetically. For our discussion here, the importance of the Fischer-Tropsch process was the demonstration that hydrocarbons could be produced synthetically on a commercial basis without the involvement of any organic materials—no microbes, no dead plants, no decaying animals. The Fischer-Tropsch process alone proves hydrocarbon fuels are not necessarily organic in origin, a point Wöhler’s synthesis of urea had prefigured a century earlier, in 1828. Some may object that the coal used in the Fischer-Tropsch process is a fossil fuel. We would add that biomass can also be used in the Fischer-Tropsch process to produce synthetic hydrocarbons. But the critical chemical reaction, as German scientists began proving in the early 1900s, was the catalytic hydrogenation of carbon monoxide (CO and H2) to form C1 hydrocarbons like methane (CH4) and methanol (CH3OH).4

During the early 1930s, the Luftwaffe, Germany’s military air force, contracted with German industrial giant IG Farben to produce a synthetic high-quality aviation fuel. Germany’s military arm, the Wehrmacht, followed suit by hiring IG Farben to produce synthetic diesel fuel. By 1936, IG Farben was no longer an independent company, but a government-private enterprise partnership run by the Nazi government. When Hitler attacked Poland on September 1, 1939, Nazi Germany had fourteen synthetic fuel plants in operation and six more under construction, producing approximately 95 percent of the aviation fuel used by the Luftwaffe. By 1943, using synthetic oil production defined by the Fischer-Tropsch process, Germany had almost three million metric tons of gasoline by hydrogenation of coal. Adding to this diesel fuel, aviation fuel, and various lubricants produced synthetically from coal, Nazi Germany was able to satisfy up to 75 percent of its fuel demand through coal conversion processes made possible by the equations developed in the Fischer-Tropsch process.5

Also constrained by lacking extensive national petroleum reserves, imperial Japan followed Nazi Germany into synthetic fuel production. In 1936, Japan calculated that the nation would have had a 400-to-500-year fuel reserve by converting coal to liquid fuel. Japan’s seven-year plan of 1937 called for the construction of eighty-seven synthetic fuel plants by 1944, all of them using the Fischer-Tropsch process. The imperial Japanese government set a goal of producing 6.3 million barrels annually of synthetic gasoline and the same quantity of synthetic diesel fuel. While the economic demands of waging war in China and across the Pacific ultimately thwarted Japan’s ambitions to produce synthetic oil, Japan still managed to construct fifteen synthetic fuel plants that reached peak production of 717,000 barrels of synthetic fuel in 1944.6

Another measure of oil’s economic value involves the United States and the Allies’ bombing over Germany during World War II. On November 3, 1944, well before the end of the war, President Roosevelt issued a directive calling for a government study to determine whether or not all the bombings served any purpose.7 What precisely did the dropping over 2.7 million tons of bombs on Europe accomplish?

The resulting United States Strategic Bombing Study produced some surprising results. The bombing attack on the German airplane industry culminated in the last week of February 1944, when the U.S. dropped 3,636 tons of bombs on German airframe plants. In that week and the days following, the U.S. and the Allies bombed every known aircraft factory in Germany. But, surprisingly, in 1944, the Nazis manufactured a total of 39,807 aircraft of all kinds. The number in 1942 before the bombing attacks began had only been 15,596. The German aircraft production had increased despite the massive bombing of Nazi aircraft plants.

As the U.S. and the Allies destroyed Germany’s aircraft manufacturing plants, the Germans adapted to recover the machinery and disperse the manufacturing. Why? The bombing devastated the buildings, but the machines “showed remarkable durability.” The Germans reorganized the management of the aircraft plants and subdivided production into many small units that were immune to massive bombing raids. The result was clear—bombing the plants had not slowed down the Nazis’ ability to make new airplanes. The Allied bombing of German oil and chemical production plants told a similar story. By the end of the war, the Germans could produce Messerschmitt fighter planes, but they had no airplane fuel with which to fly them. The output of aviation gasoline from synthetic plants fell from 316,000 tons per month, when the air attacks began in 1943, to 5,000 tons in September 1944, when the U.S. and the Allies had bombed every primary airplane manufacturing plant. Without fuel, the Nazi war machine came to a grinding halt.

In his 2021 book Stalin’s War, Bard College history professor Sean McMeekin noted that in the early stages of World War II, the British and French developed a plan for waging war on the Soviet Union.8 On January 4, 1940, the British war cabinet discussed bombing the Baku oil fields. The British knew that three-quarters of Russia’s petroleum production came from the Baku oil fields in Azerbaijan, then a part of the Soviet Caucasus. On March 28, 1940, at a Supreme War Council in Paris, the British and French formalized their plans for bombing Soviet oil installations in Baku, later code-named Operation Pike. On April 1, 1940, the British Air Ministry ordered four squadrons of Bristol Blenheim Mk IV bombers, a total of forty-eight bombers, to redeploy and reinforce Britain’s Middle East command in Iraq. The British Air Ministry acted after a military reconnaissance flight over the Baku oil fields reported the wooden oil derricks along the Caspian Sea were only seventy yards apart. The ministry realized “incendiary bombs could easily ignite a conflagration of the entire petroleum-saturated area.”9 The bombing raid never happened. Still, McMeekin allowed himself an exercise in hypothetical history. He mused that a British air attack on the Baku oil fields could have created “an alternative world in which the war machines of Stalin and Hitler might have slowly ground to a halt for the lack of oil in the weeks after May 15, 1940.”10

Anthony N. Stranges, Department of History, Texas A&M University, prepared for presentation at the AIChE 2003 Spring National Meeting, New Orleans, LA, March 30-April 3, 2001, unpublished.

Henry H. Storch, Ph.D., chief, Research and Development Branch; Norma Golumbic, M.S., technical assistant, Research; and Robert B. Anderson, Ph.D., physical chemist, Research and Development Branch, Office of Synthetic Liquid Fuels, Bureau of Mines, U.S. Department of Interior, Pittsburgh, Pennsylvania, The Fischer-Tropsch and Related Syntheses (New York: John Wiley & Sons, Inc., 1951), pp. 1-3, and 11. Again, this chapter will closely footnote all sources. When possible, discussions from the sources will be paraphrased if not quoted directly. When paraphrasing adds undue complexity to the text, word-for-word sections will be used here, as sparingly as possible.10

Ibid.

G.A. Somorjai, “The Catalytic Hydrogenation of Carbon Monoxide. The Formation of C1 Hydrocarbons,” Science and Engineering, Volume 23, Issue 1-2 (1981; published online December 5, 2006), pp. 189-202.

“The German Document Retrieval Project,” Center for Energy & Mineral Resources,” Texas A&M University, September 20, 1977.

Paul Schubert, Steve LeViness, and Kym Arcuri, Syntroleum Corporation, Tulsa, Oklahoma, and Anthony Stranges, Texas A&M University, “Fischer-Tropsch Process and Product Development During World War II,” April 2, 2011, unpublished paper, at Fischer-Tropsch.org, under “Primary Documents/Presentations.”

The United States Strategic Bombing Survey. The European War report was the first completed, published by the Government Printing Office on September 30, 1945. This report as originally issued can be read on the Internet at the following URL: http://www.anesi.com/ussbs02.htm#page1.

Sean McMeekin, Stalin’s War: A New History of World War II (New York: Basic Books, 2021), pp. 134 and 153-155.

Ibid., p. 154.

Ibid., p. 155.